Zentech Zenlock – Oil Exploration Animation

Trinity artists show off their impressive 3D rendering skills during an oil well drilling animation focusing on the Zenlock Fixation System jackup units. Trinity’s realistic renderings accurately represent the complex structure and teaches viewers about how the jackup unit operation system works, through 3D visuals.

This oil well drilling animation begins with a stunning view of the realistically rendered 3D model of the Zentech oil rig, completely surrounded by ocean. The virtual camera rotates around the oil rig allowing viewers to observe the large structure fully in the round.

The focus of this oil well drilling animation is the operation process of the Zenlock jackup system which is installed directly below the jacking pinions on each leg cord of all three legs. The Zenlock directly transfers hull elevated weight and environmental loads between the leg and hull of the jackup, through the engagement of the Zenrack to the leg rack plate. First, the oil rig is displayed being jacked up on location. Once the jackup unit is lifted to the required air gap, each Zenlock is engaged one at a time.

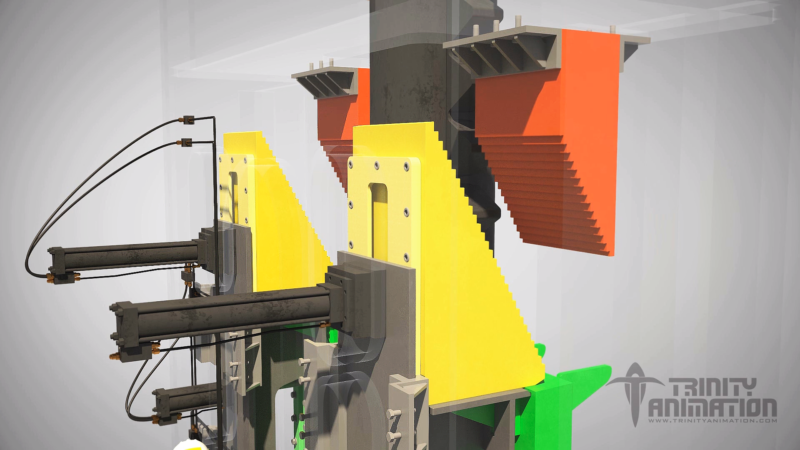

To begin demonstrating the jackup system, the camera zooms in on one specific leg. Through 3D software, Trinity artists make the Zenlock housing transparent so that viewers have the ability to observe the interior parts of the Zenlock system and understand how it operates. Trinity artists apply different colors to the different parts of the jackup so that viewers can distinguish the different items. Inside the Zenlock housing, the lifting table is displayed in dark grey, which supports the left and right zenracks that are displayed in green. The left and right lower movable wedges are displayed in yellow, and the left and right fixed upper wedges are displayed in orange. All four wedges have serrated surfaces allowing differential penetration by each of the three jackup legs through mechanical adjustments. When engaged, each Zenrack is able to carry a total load of 3,175 metric tons. The Zenrack is machined with a bump in the lower surface of each tooth to ensure that the point of load transfer from the Zenrack to the rack plate occurs at that specific location closer to the root of the rack plate. At this stage, there is a small gap between the Zenrack teeth and the rack plate. The two green Zenracks are engaged one by one. This procedure is repeated for all three cords of all three legs.

After the proper engagement of all Zenracks and movable and fixed wedges, the hull is lowered by turning the pinions, and transferring the load to the Zenracks. At this point, the jackup rig is ready to perform onsite operations in a fully jacked up and safe position. Once onsite operations are completed, the jackup is ready to be jacked down. The pinions elevate the jackup slightly to take the load off of the Zenracks. Now the wedges can be easily retracted and the hull is jacked down to the water. The oil well drilling animation ends with a beautiful aerial shot rotating around the oil rig in the water.