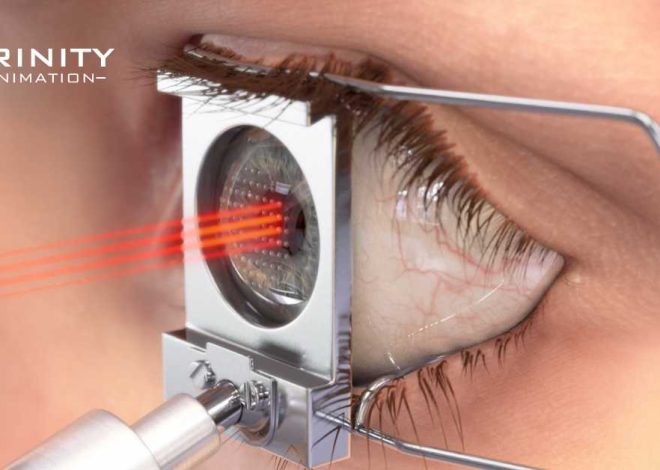

Oil States Multi-Segmented CLamp-Mechanical Animation

Trinity Animation creates an impressive mechanical animation demonstrating the Oil State’s underwater pipeline system’s multi-segment clamp installation.

The Oil States Pipeline End Manifold (PLEM) and Pipeline End Termination (PLET) systems are typically used in new construction where a pipeline terminates or needs to be jumpered to another location, such as an FPSO, refinery, holding tank, etc. Industry terms set out in boldface are defined in this post.

A PLET is the end or termination of a pipeline.

The FPSO (Floating Production Storage and Offloading) system is used extensively by oil companies for the purpose of storing oil from the oil rigs in the middle of the ocean and in the high seas. It is one of the best-devised systems to have developed in the oil exploration industry in the marine areas.

The FPSO, as its name suggests, is a floating contraption that allows oil rigs the freedom not just to store oil but also to produce or refine it before finally offloading it to the desired industrial sectors, either by way of cargo containers or with the help of pipelines built underwater.

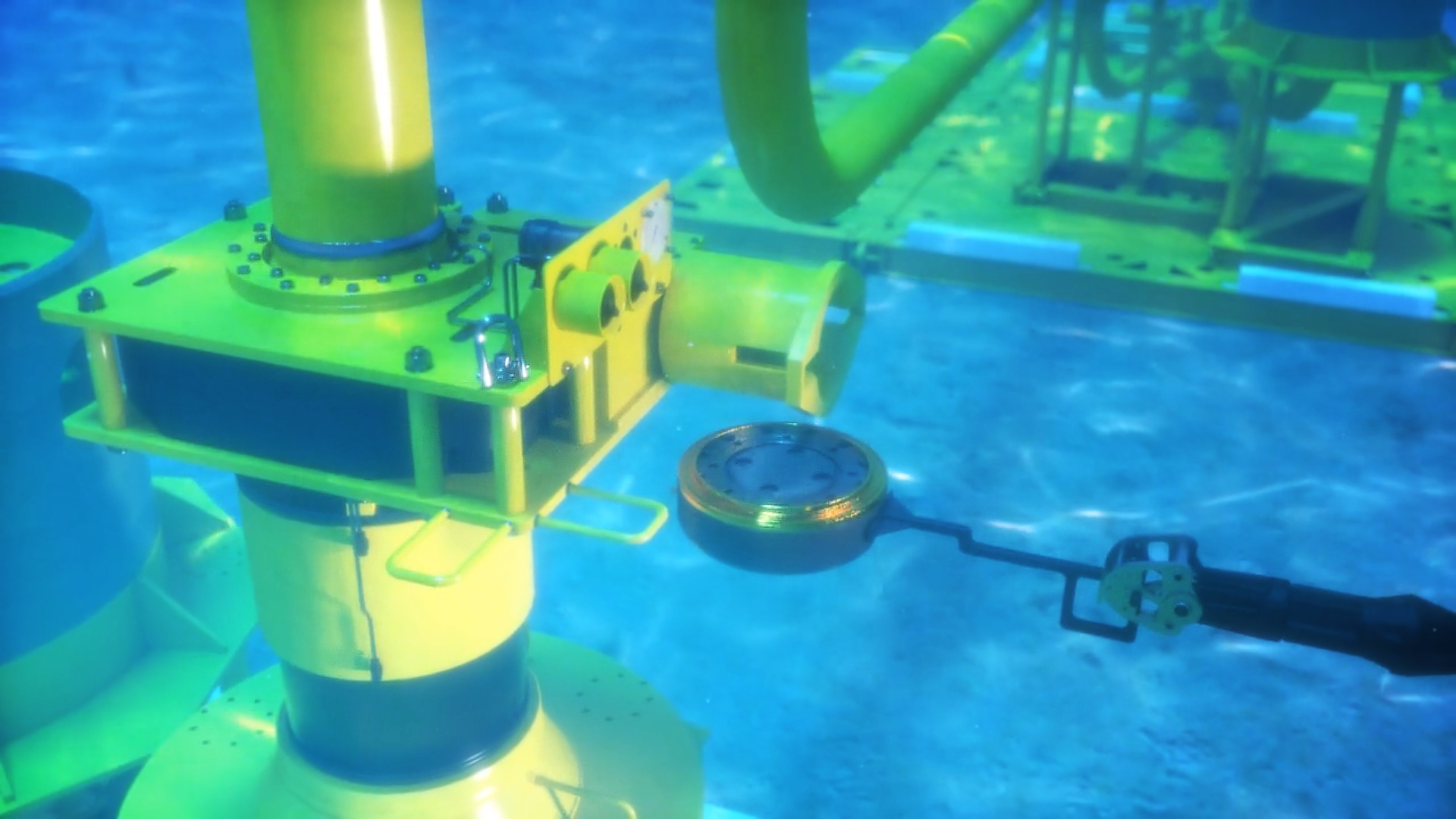

This mechanical animation produced by Trinity illustrates how Oil States’ multi-segment clamp-style connector is ideal for many deepwater applications. The clamp is designed for easy installation of jumpers, tiebacks, and flowlines via remote operated vehicle (ROV) interface. In subsea oil/gas production systems, a subsea jumper is a short pipe connector that is used to transport production fluid between two subsea components. A subsea tieback, on the other hand, is a connection between a new oil and gas discovery and an existing production facility. Lastly, subsea flowlines are used for the transportation of crude oil and gas from subsea wells, manifolds, off-shore process facilities, loading buoys, subsea to shore, as well as re-injection of water and gas into the reservoir.

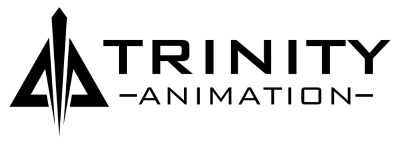

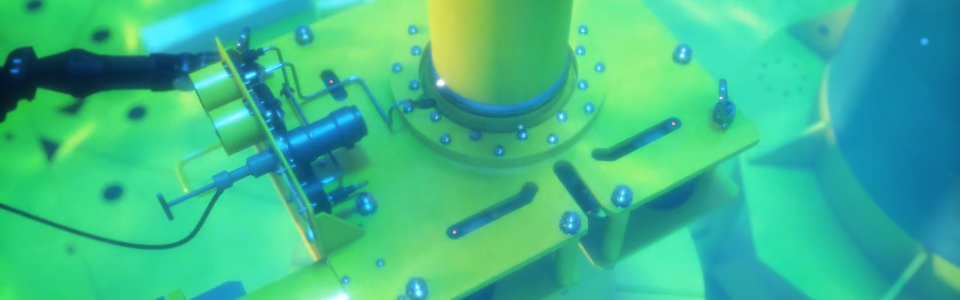

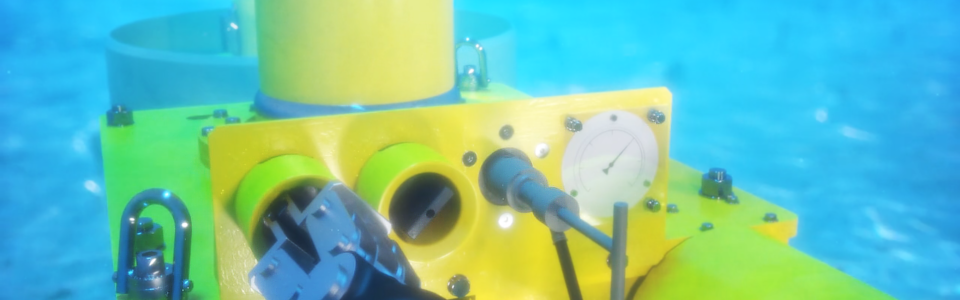

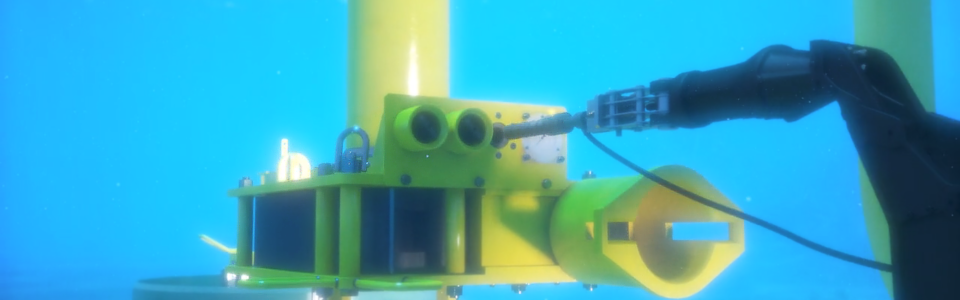

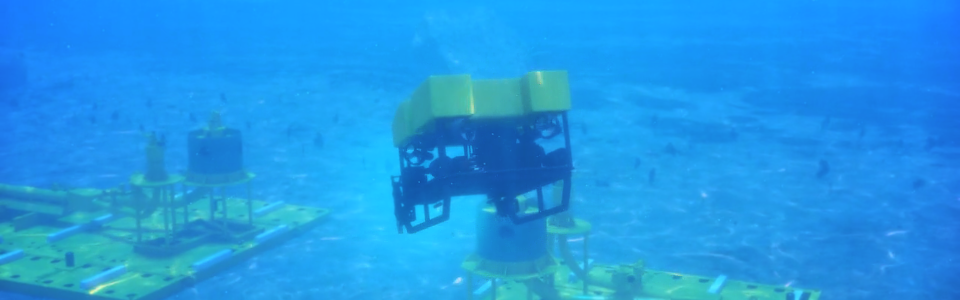

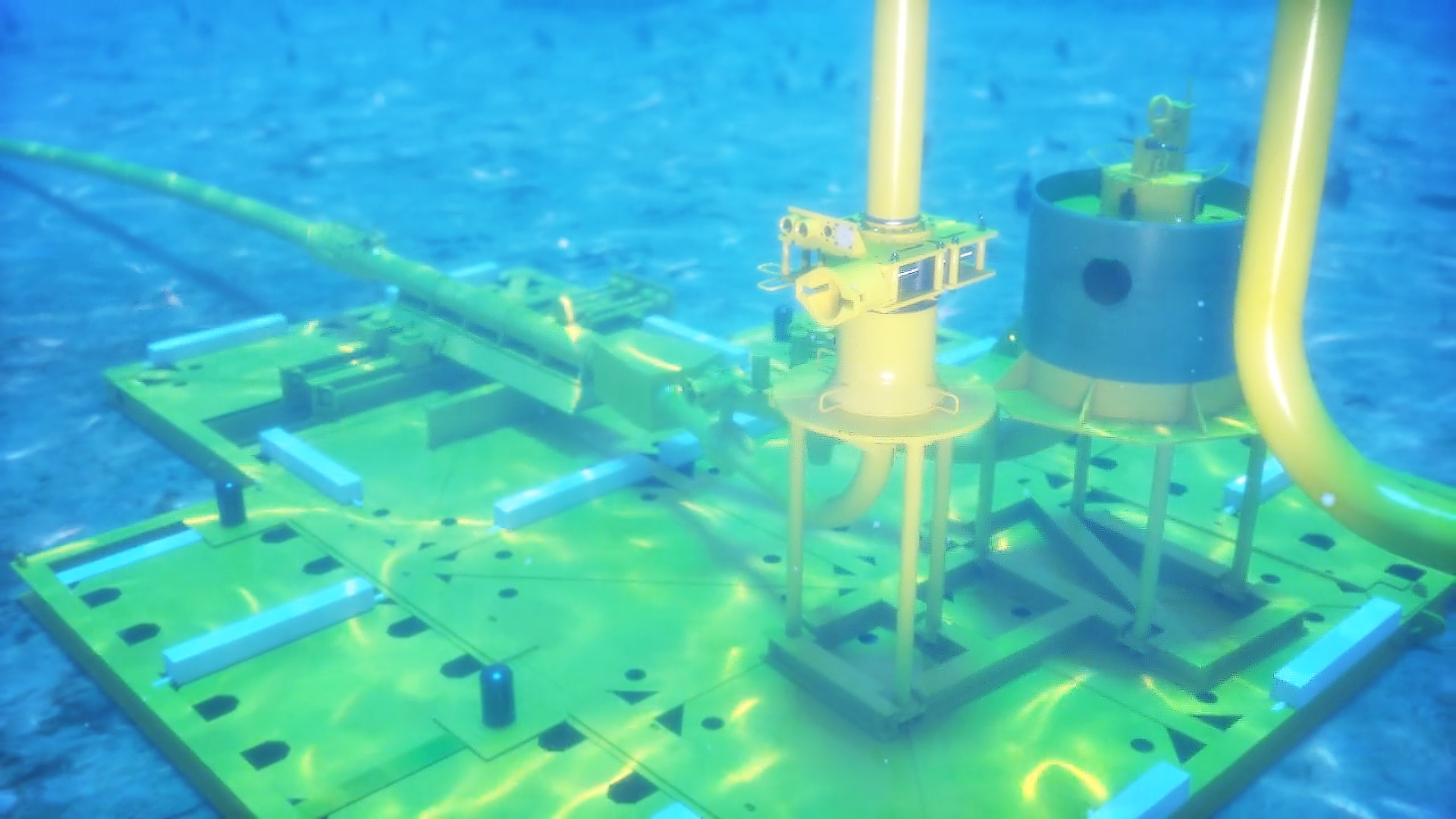

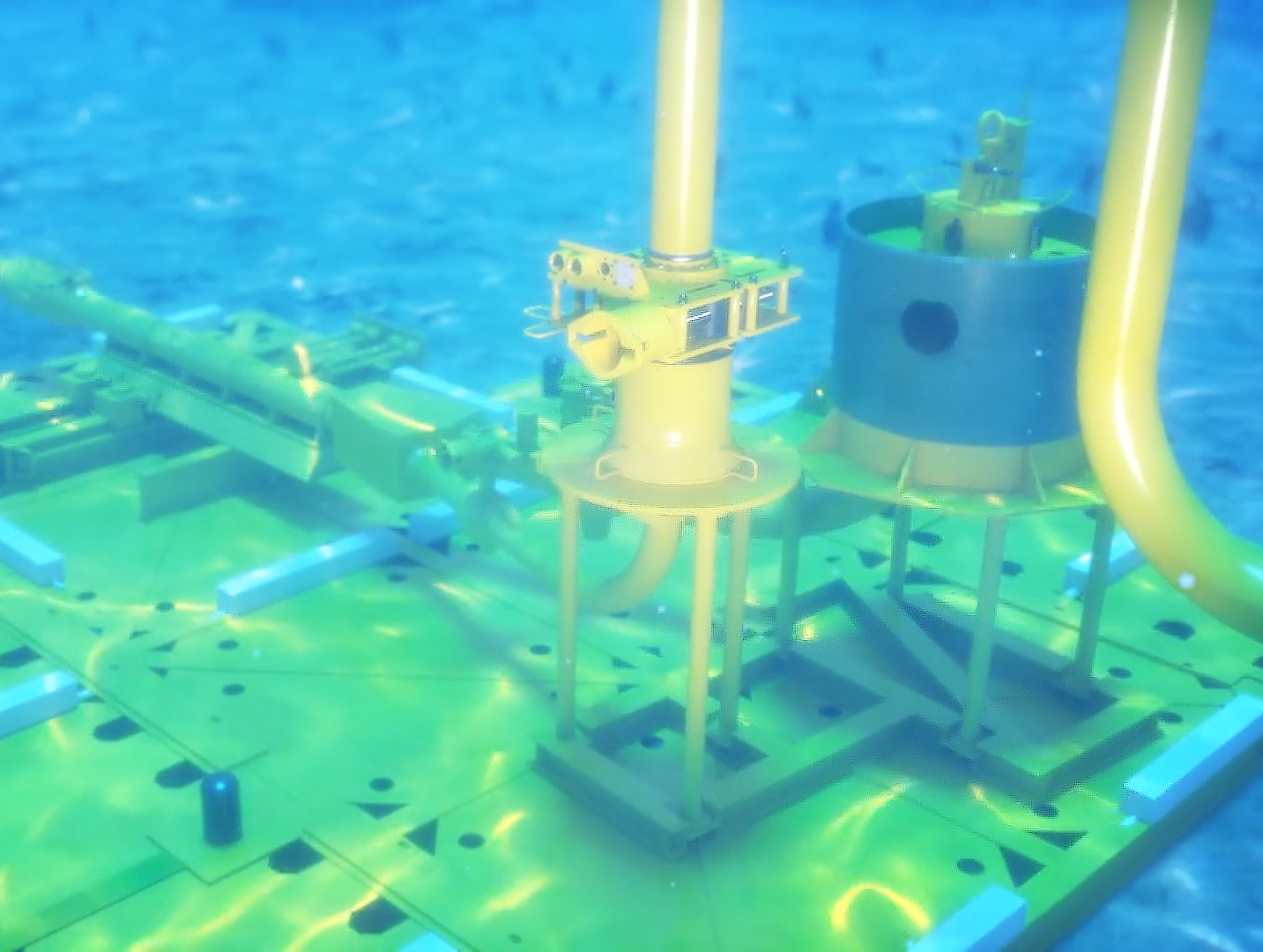

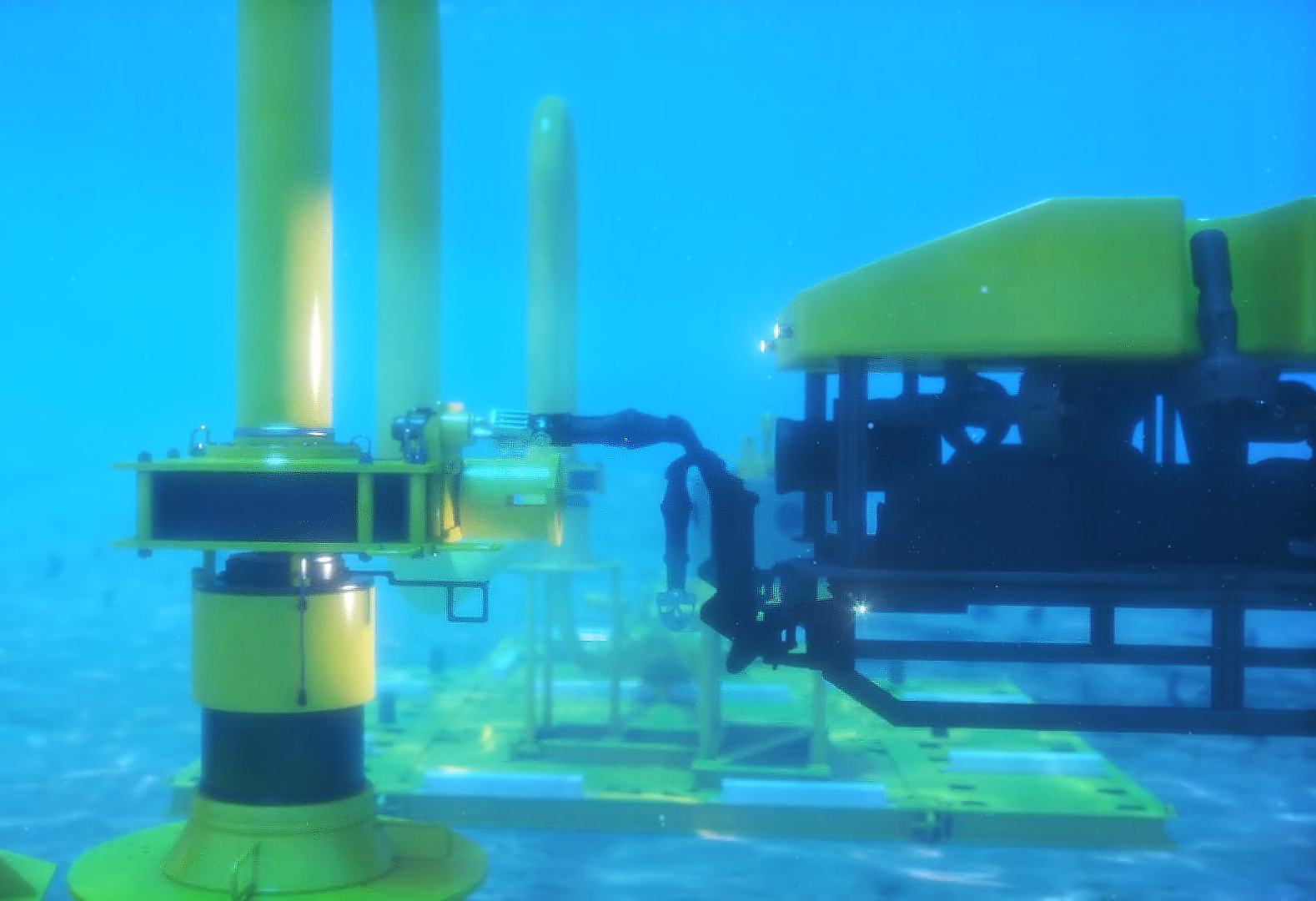

The opening scene of the mechanical animation shows a Pipeline End Manifold (PLEM) PLEM and a Pipeline End Termination ( PLET ) device already in place. Pipeline End Manifold (PLEM) and Pipeline End Termination (PLET) systems are typically used in new construction where a pipeline terminates or needs to be jumpered to another location, such as a Floating Production Storage and Offloading System FPSO), refinery, holding tank, etc. The mechanical animation continues on to show how the distance between the PLEM and the PLET is measured to ensure proper length for the new jumper. The jumper is custom fabricated with the clamp connectors in place and ready for installation. The action of the ROV is shown removing the caps from the PLEM and the PLET. The ROV turns the hub valve to release pressure, pulls the pin, and allows the hook line coming down from topside to lift away the caps. The ROV then uses a cleaning tool to prep the hubs for the seal interface. This is to ensure a clean sealing surface for the clamp connector. This process lowers the fabricated jumper from the topside service vessel, with the clamps already installed on each end.

The ROV guides the landing of the jumper by providing camera assistance to the topside operator. The ROV operator “lands” each end independently to ensure proper sealing. Once this landing process is complete the ROV is ready to begin the final installation sequence. The mechanical animation demonstrates how the Oil States “soft-land” system reduces the risk of seal or hub damage which could otherwise be caused by hard-landings. The mechanical animation also clearly shows the ROV inserting the “hot stab” and turning the valve. Next, the ROV engages the torque bucket. The threaded screw is shown drawing the clamp segments together surrounding the hubs. The hubs from the PLET and the hub from the jumper are drawn into contact and a metal seal is compressed between the two surfaces. The ROV continues and performs an annulus seat test via the hot stab interface. The valve is opened, the pressure is verified to 10,000 pounds per square inch (p.s.i.) and the valve is then close to maintaining the pressure enveloped.

The viewer readily sees how Trinity’s artists allow a complete visual explanation of the processes involved in subsea oil exploration. The environment pictured in this animation is particularly dangerous for human divers and the use of the ROV is crucial. Similarly, the visual conditions of the sea oil operations make it very difficult to obtain clean images through the use of a physical camera. Trinity’s artists created a complete and accurate undersea environment.