Wakarusa Wastewater Treatment Site – Sales Animation

This sales animation produced by Trinity 3D exhibits a Wastewater Treatment Site located in Wakarusa, Kansas for their client, Black and Veatch. This plant improves the city of Wakarusa’s ability to manage heavy rainfall and nutrient pollution as well as enable additional development. The plant will increase the capacity of the Lawrence, Kanas city sewer system by 2.5 million gallons per day, or by about 20 percent. The main plant covers about 25 acres and includes labs, water storage, control stations and nutrient-removal basins. The plants cleaning process has four main steps: trash removal, biological nutrient removal, final clarification to remove solids, and disinfection through ultraviolet bulbs.

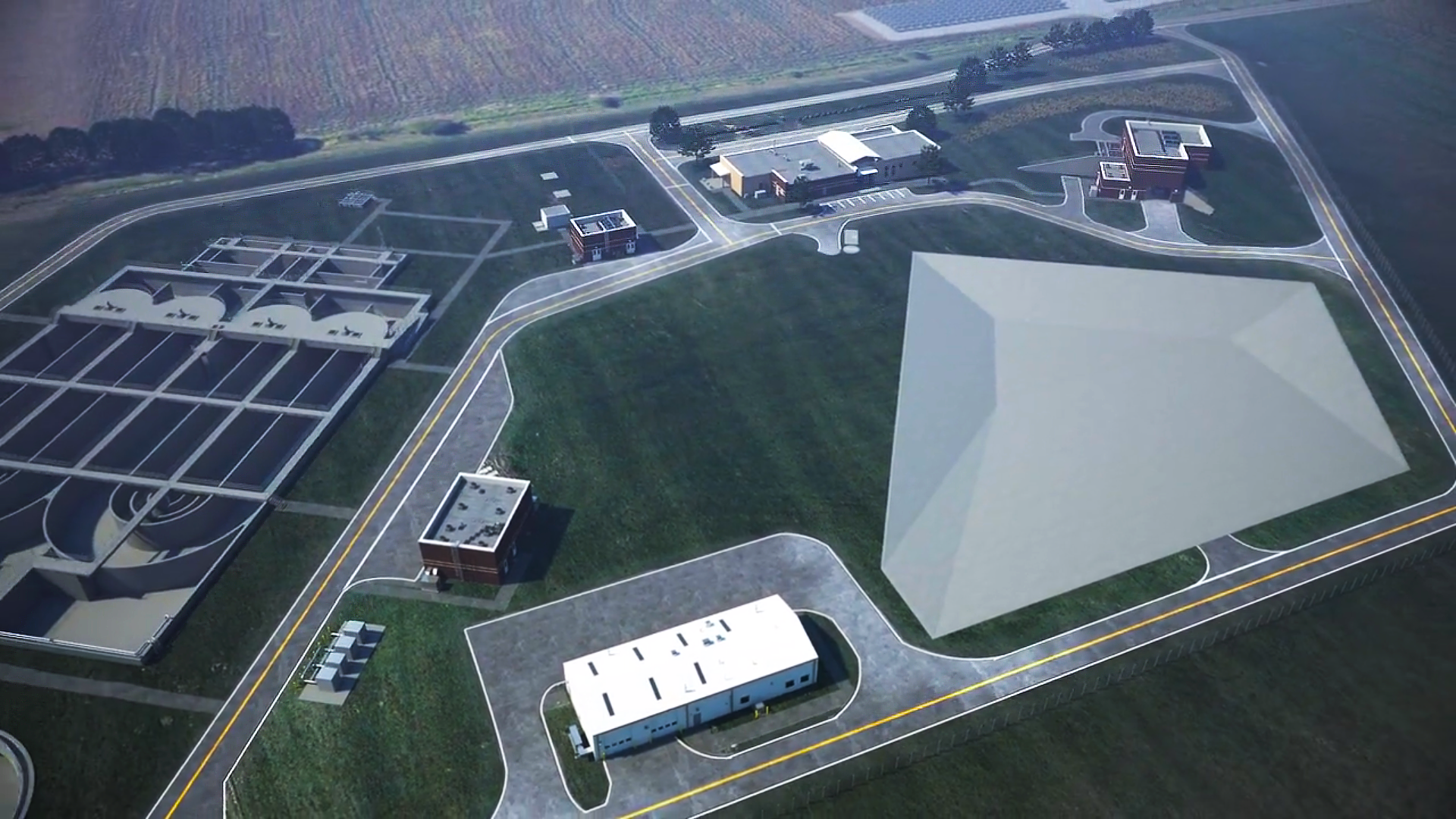

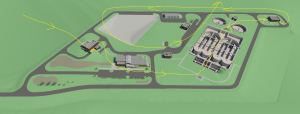

Through 3D animation, Trinity artists develop an accurate replica of the Wakarusa Wastewater Treatment Site. They’ve manipulated the camera around the 3D modeled site to display it at many different angles and perspectives. The entire sales animation is one continuous camera shot – providing viewers with an in-depth tour of the wastewater plant while engaging viewers with unique visuals that would be difficult to obtain with live footage. Viewers are exposed to aerial views of the site, as well as moving camera shots that travel through the buildings or pan over the site.

The first image displayed in the sales animation is the pump station, which the camera rotates around so viewers get a complete view of the structure. The camera then zooms out to an extreme aerial view until both the pump station and the wastewater treatment plant is in site. A blue line develops, forming the path from the pump station to the wastewater plant. The camera then begins to zoom in on the wastewater treatment plant.

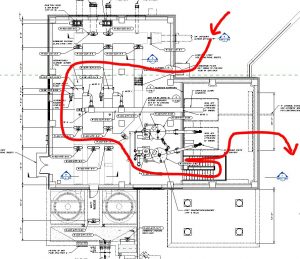

As the camera zooms in on the wastewater treatment plant, it approaches an individual building known as the headworks building. The camera projects through the window of the door where it proceeds to tour the interior of the building, displaying detailed visuals of the 3D rendered equipment. The fluid and unique movement of the camera engages viewers as it exhibits the equipment. The camera then exits the building through a different opening and zooms out once again. The camera provides a birds-eye view while gliding over the site until it reaches the UV disinfecting building. The camera enters through an open door and slowly maneuvers through the building and exits through the other end of the building. Once the camera exits, it rotates around providing a view of the entire plant. It then pans the site from a high angle camera point of view and finally zooms out giving viewers one last aerial view.

Trinity artists accomplished this sales animation through reference photographs and illustrations which guided the artist through the development of the 3D imagery. Aerial view illustrations of the site were provided by Black and Veatch. They mapped out the entire site and each individual building, which instructed Trinity artists where to place the camera path. It is Trinity’s goal to meet the customer’s needs which they successfully completed in this animation by providing a complete tour of the Wakarusa Wastewater Site effectively, through 3D animation.

New Wastewater Treatment Plant for Lawrence, Kansas:

Melinda Harger, a utilities manager with the City, explained that the plant’s cleaning process has four main steps: an initial grit and trash removal, biological nutrient removal, final clarification to remove solids, and disinfection via ultraviolet bulbs. The new plant’s nutrient removal step will ensure the city meets Kansas Department of Health and Environment and federal Environmental Protection Agency requirements. Harger said the city must ensure that the amount of nitrogen, phosphorus and ammonia in the water released into the river are below certain levels because too much can harm the ecosystem.

For instance, too much nitrogen and phosphorus in the water — a form of nutrient pollution — can cause large algae blooms that harm water quality and decrease the oxygen that fish and other aquatic animals need to survive, according to the Environmental Protection Agency. The EPA states that nutrient pollution has impacted many streams, rivers, lakes, bays and coastal waters for the past several decades, resulting in serious environmental and human health issues.

The new plant is also designed to reduce the amount of rainwater that enters the current plant during large rainstorms, which can reduce overflows of sanitary sewers into waterways. The Wakarusa plant includes a 5-million-gallon basin that Harger said will help the city manage heavy rainfall and reduce overflows.