3D Printing Service for New Mizzou Basketball Arena

As the design for the new basketball arena for the University of Missouri took shape in 2003, R&D Prototype asked Trinity Animation to help develop a model that could be made to a physical “rapid prototype” via the laser sintering machines available at R&D. The process required a skilled animator to go through each element of the 3D model to make sure it was perfectly formed and welded. Any 3D model printing service will require a well-formed 3D model before the process of printing can begin.

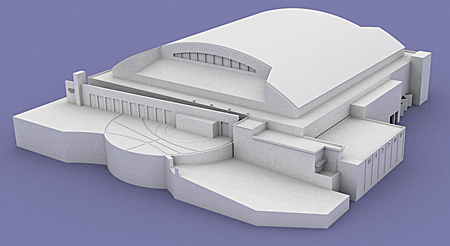

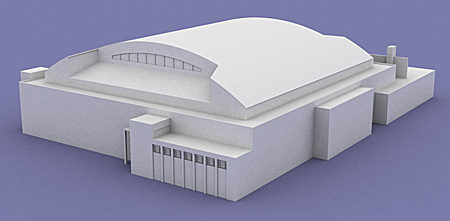

The 3D model Trinity Created is absolutely water-tight (lacking in any openings between any 2 polygons) and ready for physical output. A CAD model was used as a starting point, but Trinity modeled over the top of this to create a perfectly booleaned/welded 3D model. At each stage the model was tested for export before the final STL model was exported from Trinity’s 3DS MAX software to an STL file format for final output at R&D Prototype.

Below are renders (using Splutterfish Brazil r/s) of the finished 3D model, ready for a 3D model printing service.

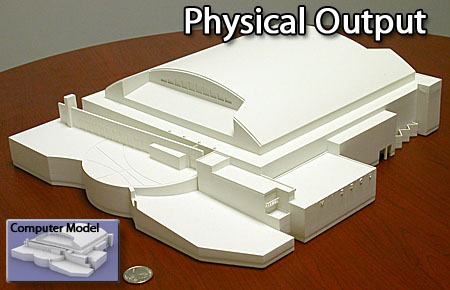

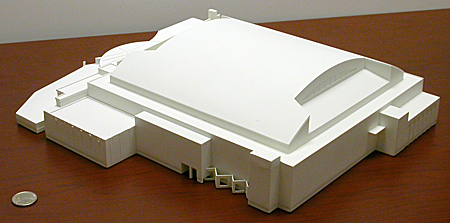

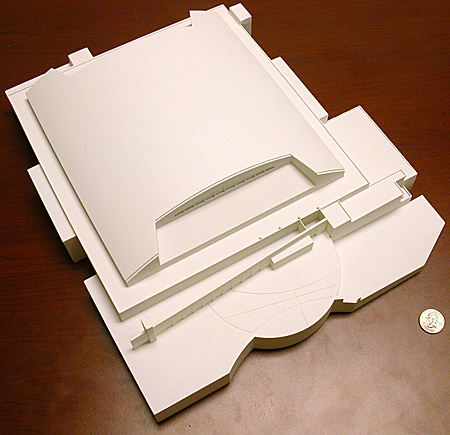

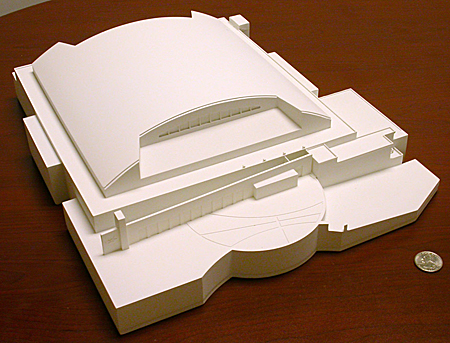

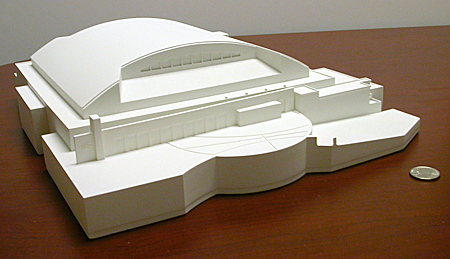

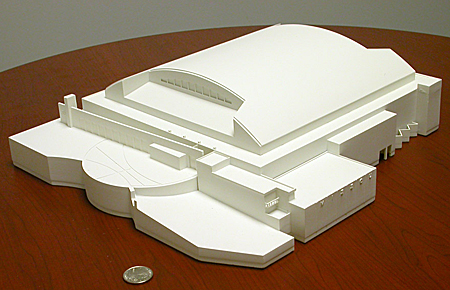

Below are photographs of the output 3D model, created by R&D Prototype. A quarter is included for scale reference. Detailed relief elements are modeled into the structure. Each smaller element is made to have a size above the minimum filament level required by the printer, so that it won’t fall off during fabrication.

[Addendum: This early work in 3D model printing service by Trinity Animation required skills that are still required for good output to a physical model — careful welding and connecting of each polygon that makes up the model, followed by STL checking the 3D model to make sure it is 100% ready for physical output. The price for physical models has come down significantly in the years since this model was printed, but the required skills remain the same – a “water tight” mesh with good dimensions for all the details.]