SpillX Fuel system- CAD Animation

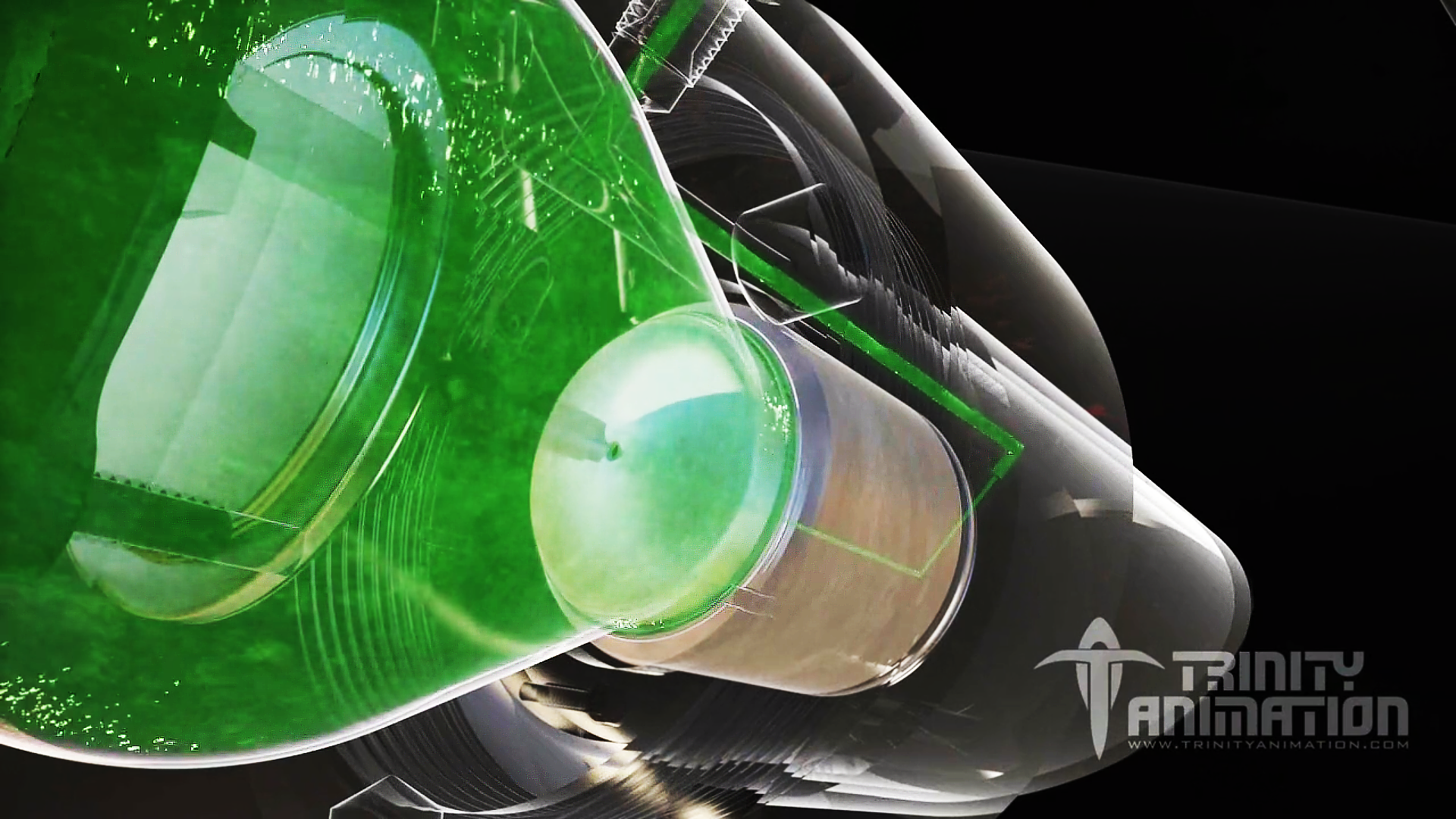

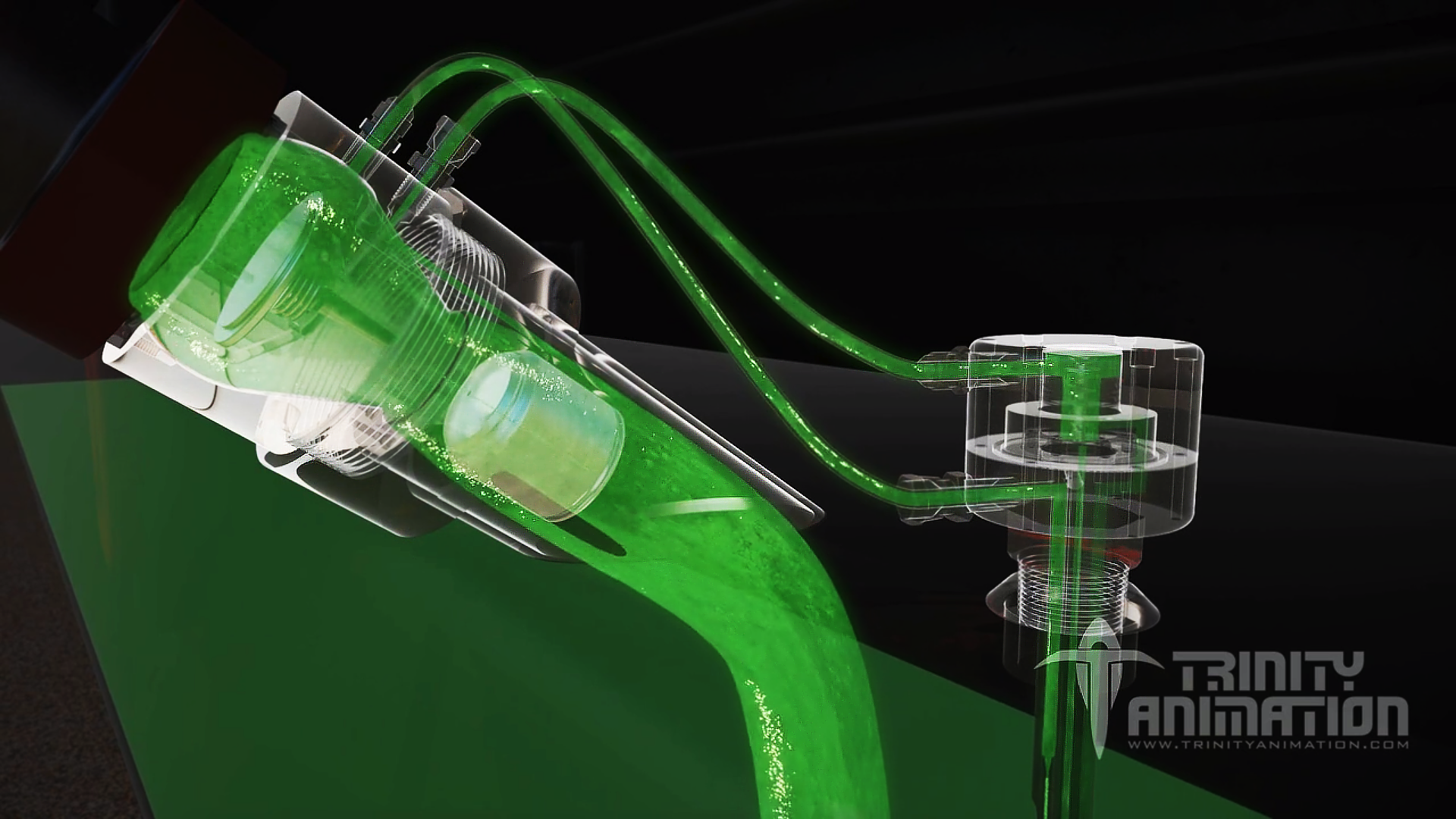

Trinity Animation has created a striking CAD animation depicting a high efficiency locomotive refueling system for its client, SpillX. Trinity’s CAD animation helped this innovative manufacturer explain the key features of its product to its business customer base.

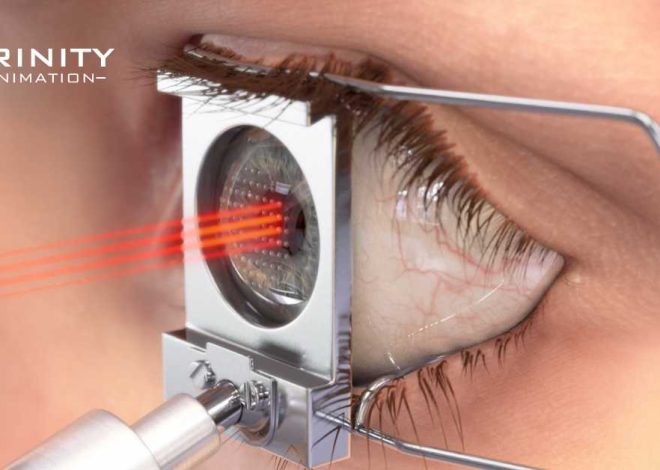

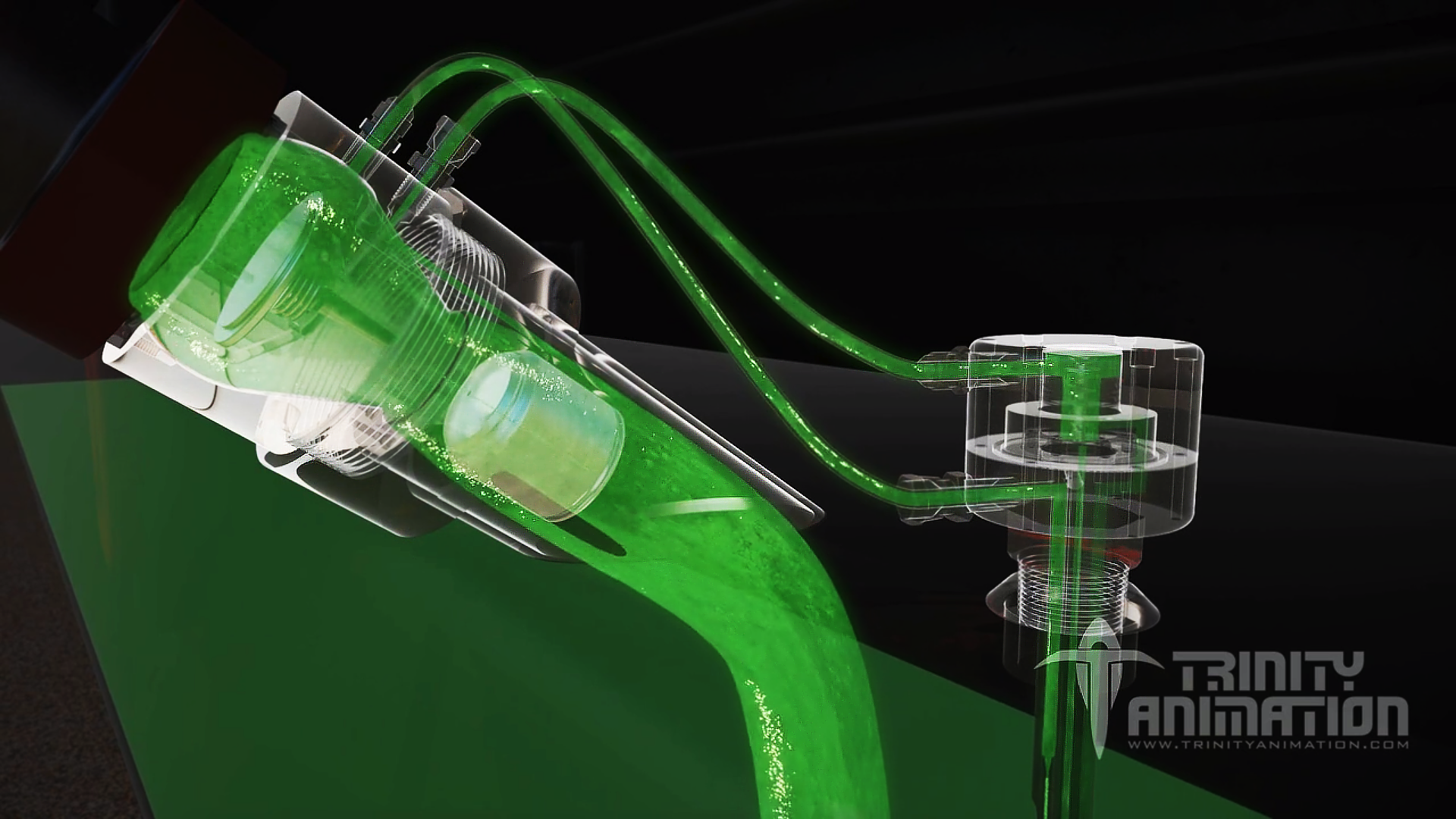

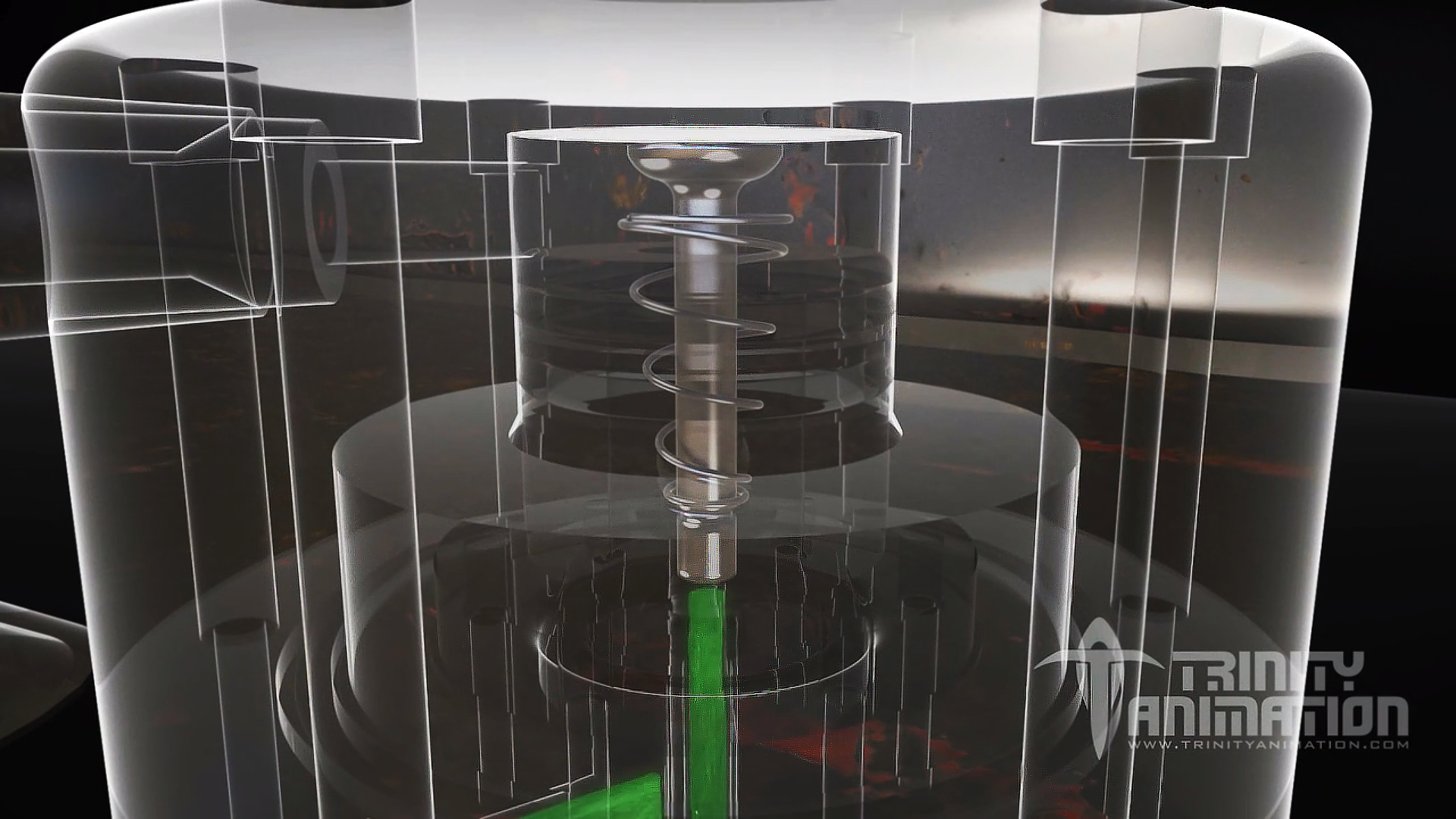

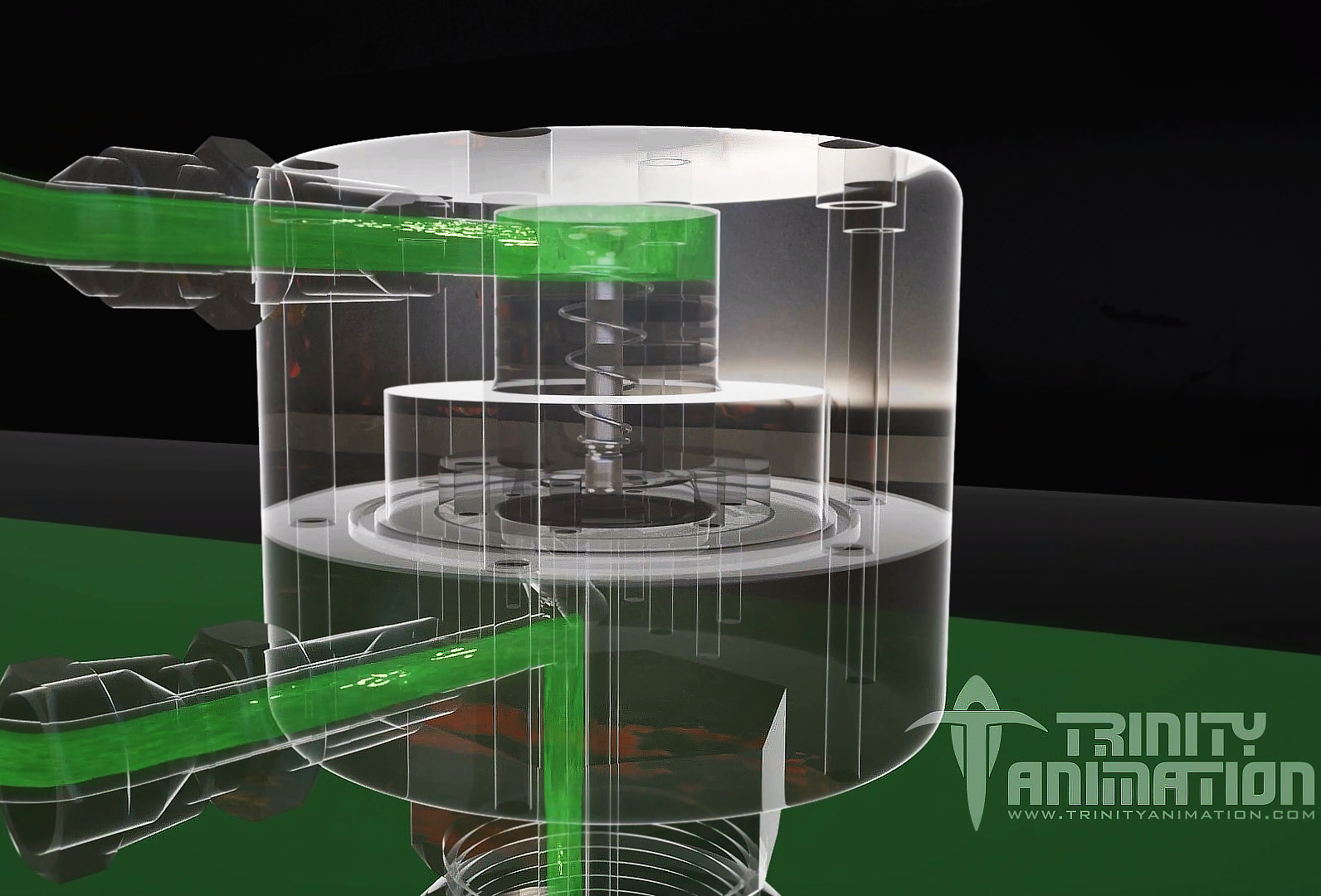

The innovation consists of an automatic shut-off system which prevents costly and hazardous fuel spills. The fueling system drew on technology developed in the aviation industry and applied it anew to the needs of the locomotive industry. This CAD animation brings to life a system that has the capacity to reach fueling rates up to 600 gallons per minute using a dry break connection which ensures no fuel at the point of disconnect. The design of the locomotive fueling system began with tested aircraft fueling technology which was then modified to suit railroad fueling needs. The new technology has proved to be robust, easy-to-use and low maintenance.

SpillX’s innovation was spurred by reports from the American Association of Railroads (AAR). The AAR has reported that the refueling systems previously in popular use by North American railroads have been reasonably reliable when properly operated and maintained. However, these same systems are subject to several types of malfunctions if not regularly maintained. Since the designs are not generally fail safe, a malfunction in the automatic shut-off system can lead to a spill due to overfilling. Conversely, improperly functioning systems are susceptible to premature shutoff. When this occurs, busy refueling personnel may override the automatic shutoff system, which can also lead to overfilling. Since most refueling takes place over spill collection systems, there is generally no release to the environment. However, the expense of the spilled fuel and the cost of the resultant waste treatment and disposal are incurred. If any spilled fuel were to reach the environment, it will lead to additional risk and expense.

Trinity’s artists began work on this CAD animation with the original engineering data supplied by SpillX. They then ensured that all aspects of the CAD animation are drawn to scale and with features of the device accurately depicted. Trinity’s artists not only correctly represented the solid components of the system, but, they also used advanced animation software to show the actual viscosity and fluid streams of locomotive diesel fuel. The result is a CAD animation that faithfully reproduces the key features of the of the fueling system, to scale, with precisely depicted materials and realistic fluid flows. Trinity’s experience in bringing routine CAD animations to vivid life can help the manufacturers of many industrial products explain and promote their ideas to their customer base.