Sahara Sand Source – Engineering Animation

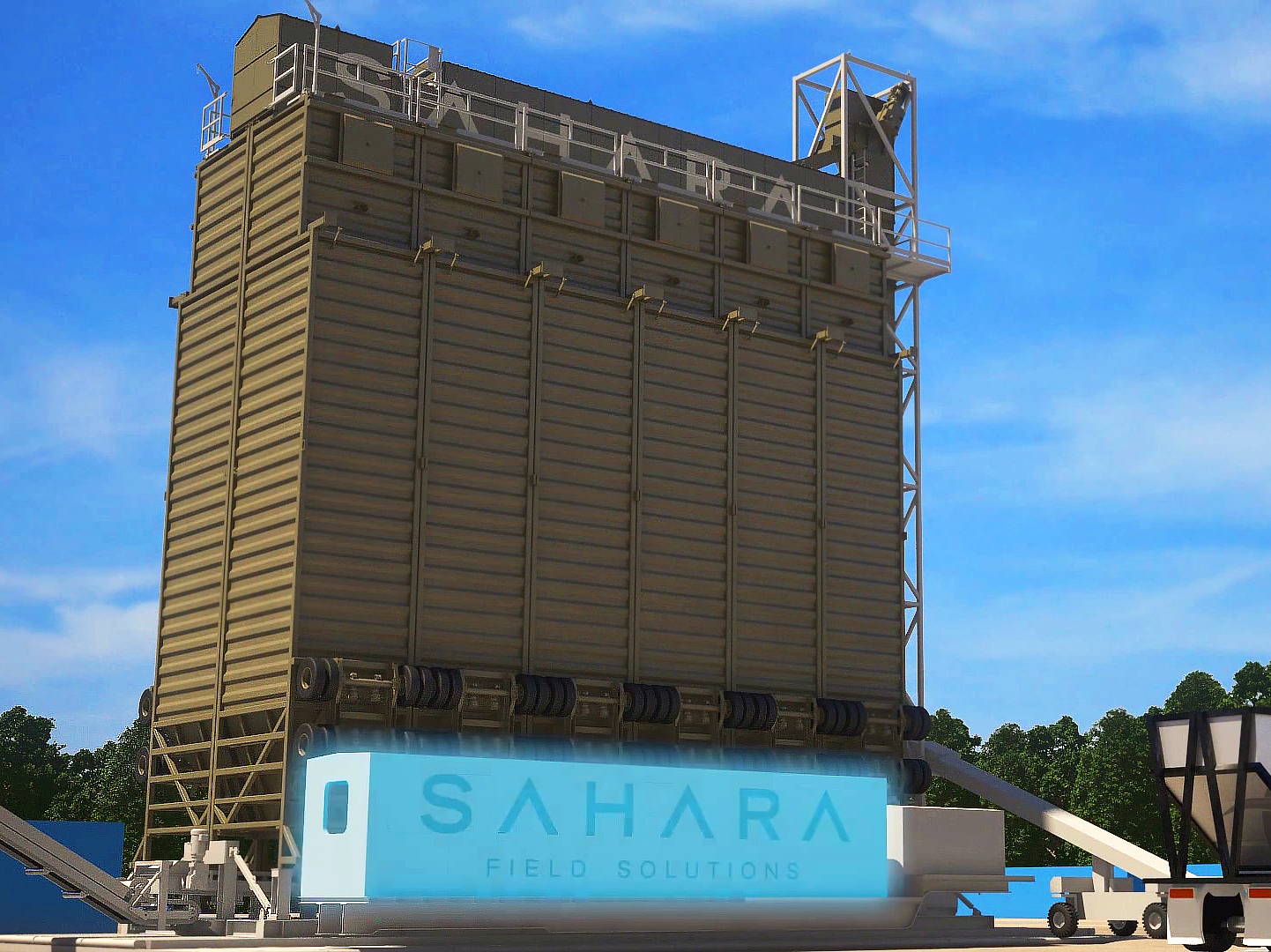

Trinity created an informative engineering animation which demonstrates the construction and operation of the complex Sahara Sand Source System. The Sahara Mobile proppant storage and handling system is an efficient, safe, and simple solution to traditional sand source methods which are slow, loud, and create dusty and unsafe work environments. The visualizations that Trinity’s 3D animations provide are an accurate representation of the actual structure and presents the material in a way that is easily understood.

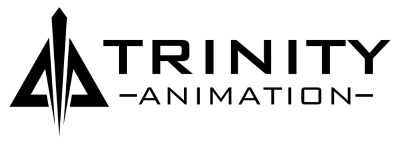

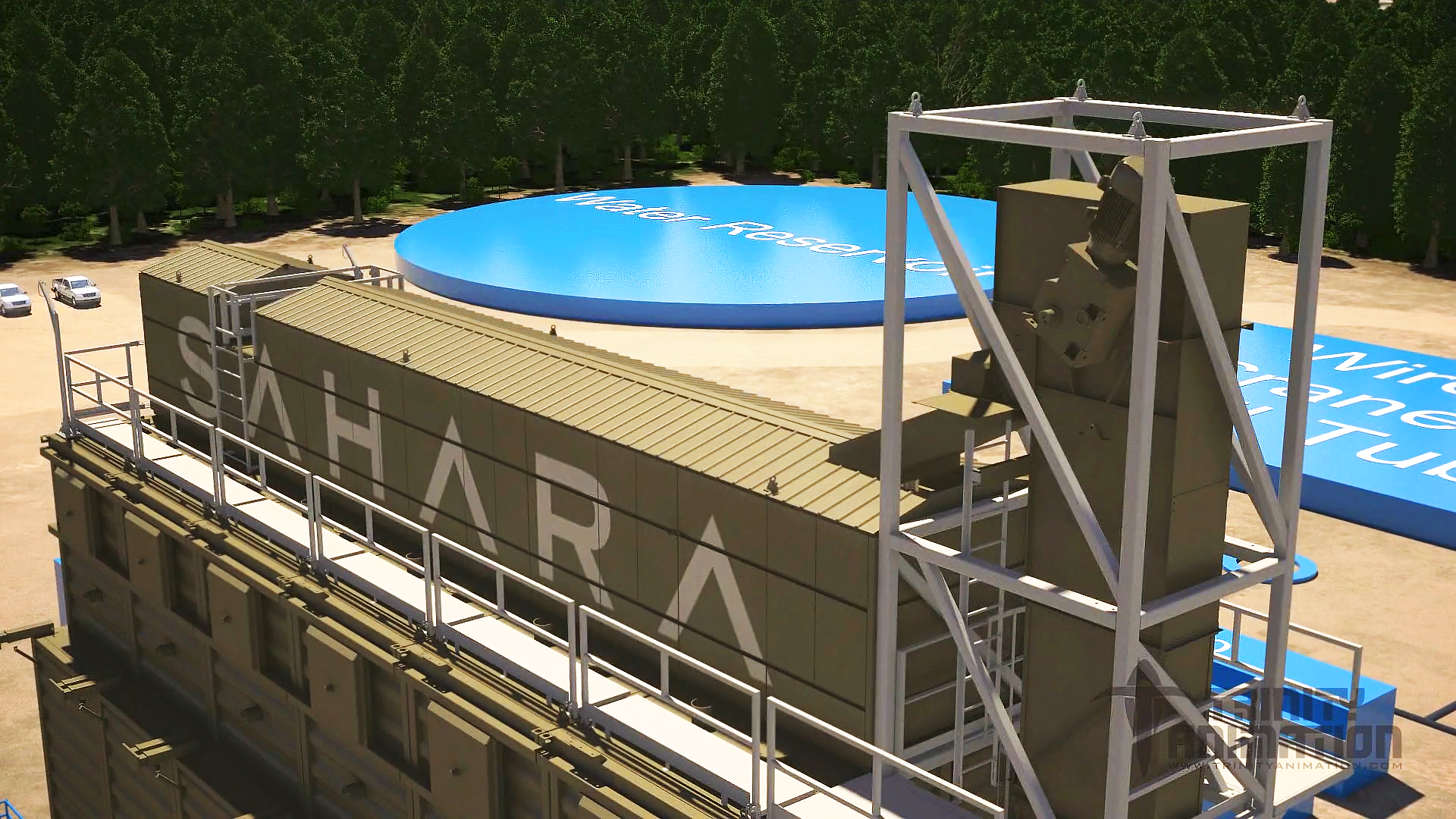

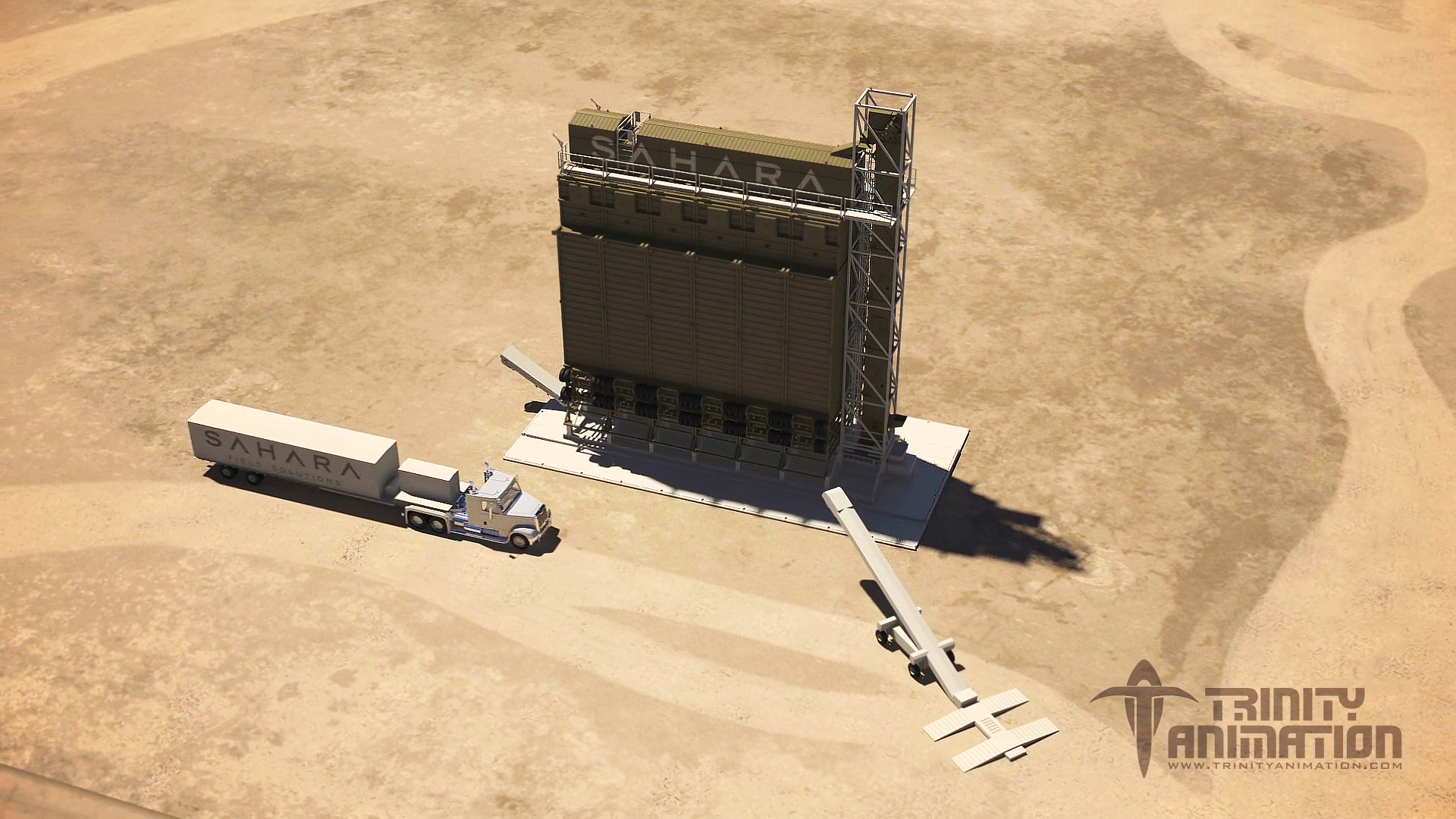

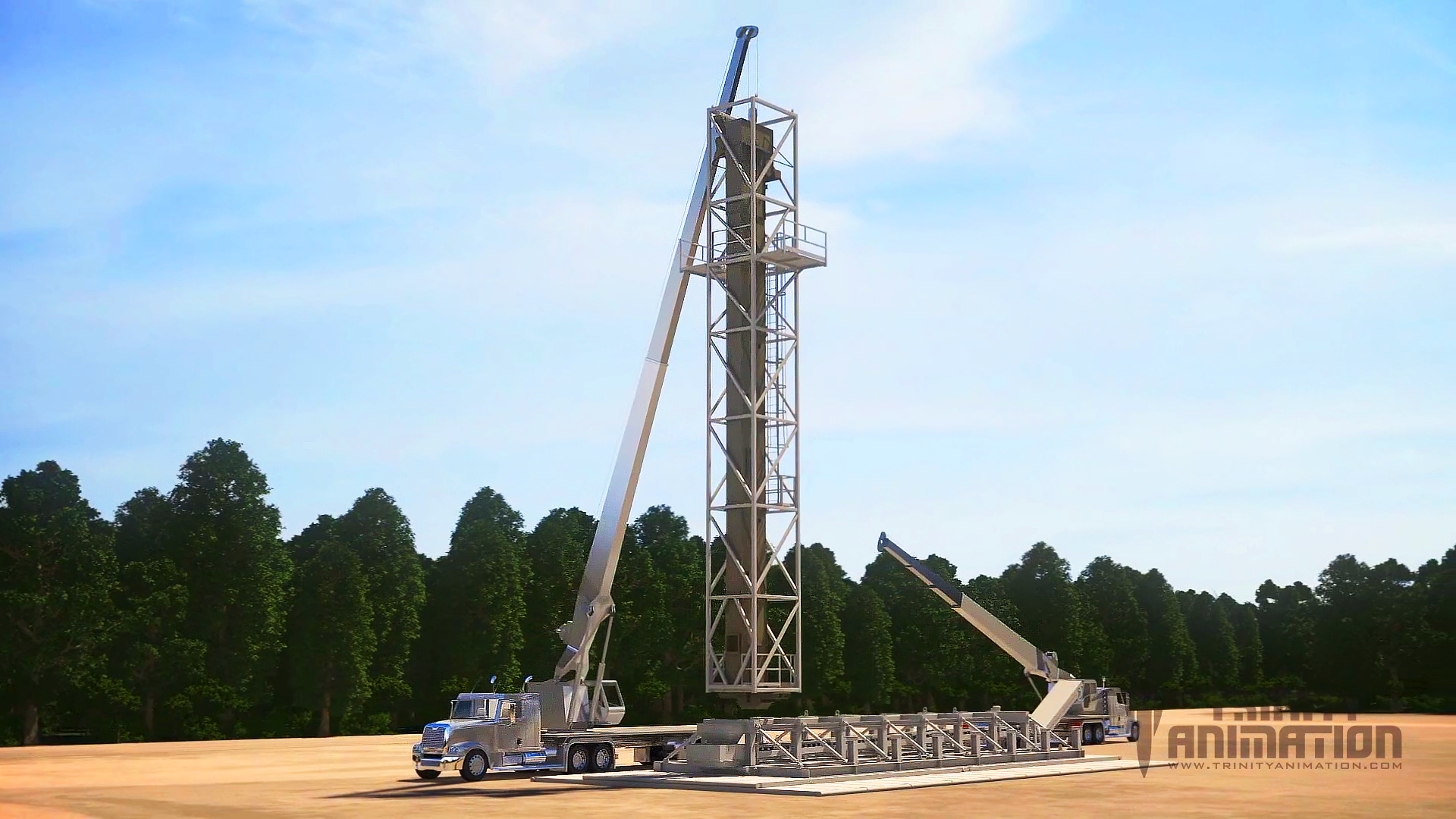

Through 3D animation, Trinity artists have created a realistically detailed replica of the Sahara Sand Source structure and its individual parts. They had the ability to easily manipulate the virtual camera to travel around the structure and provide viewers with many different angles and perspectives. A “virtual camera” is the point of focus or point of view of the animation as determined by the animator working “inside” the software. Trinity artists also included accurate imagery of the equipment involved in the construction process such as the vehicles, a crane, picker, and more. Details in the environment such as the realistically rendered sky and foliage generate stunningly pleasing visuals as well.

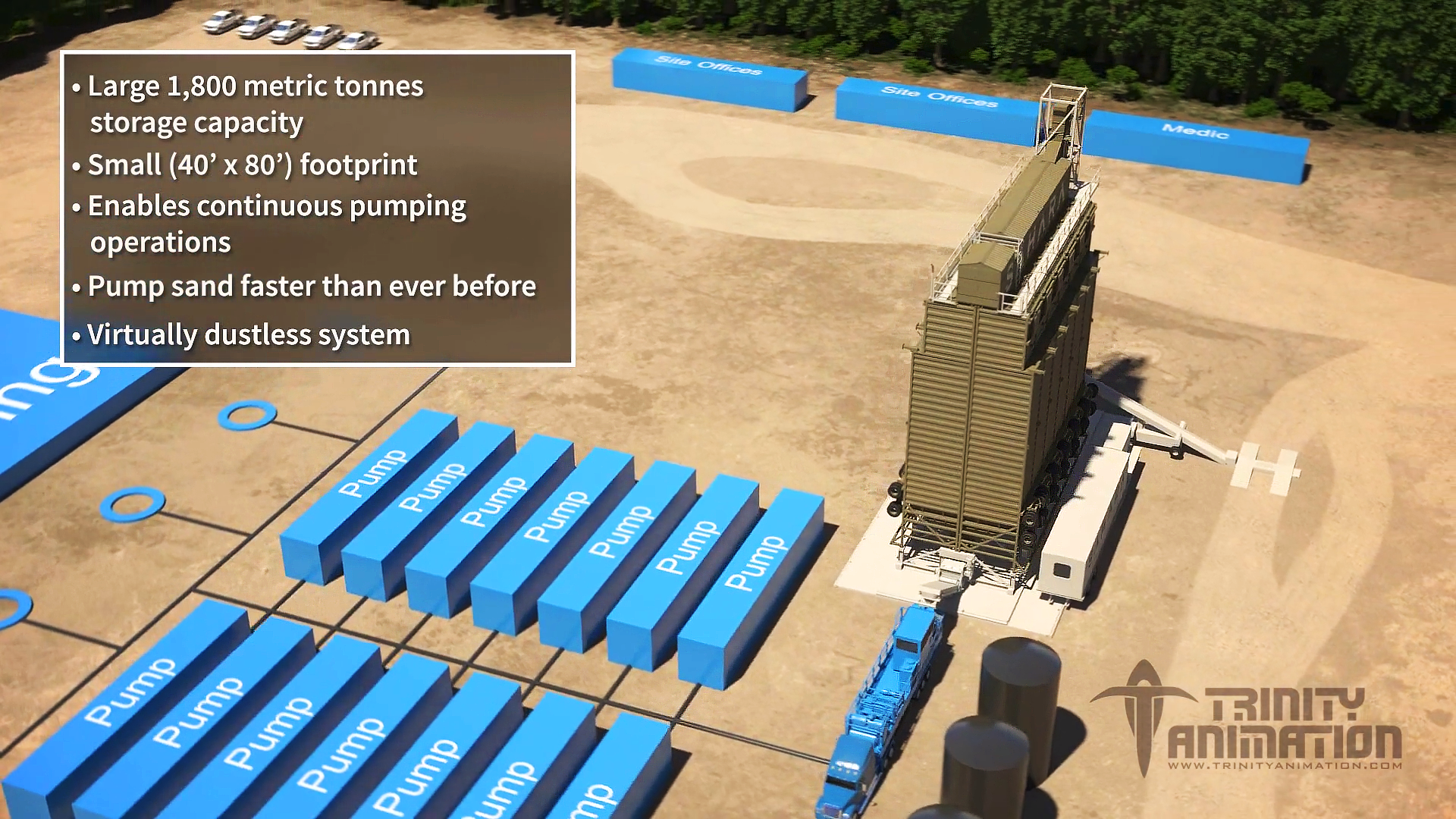

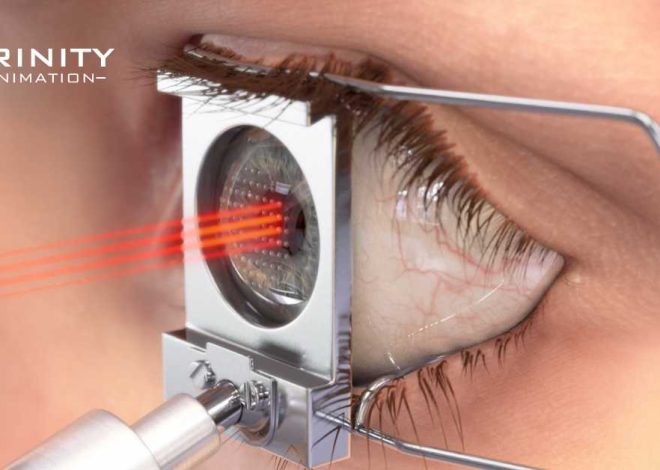

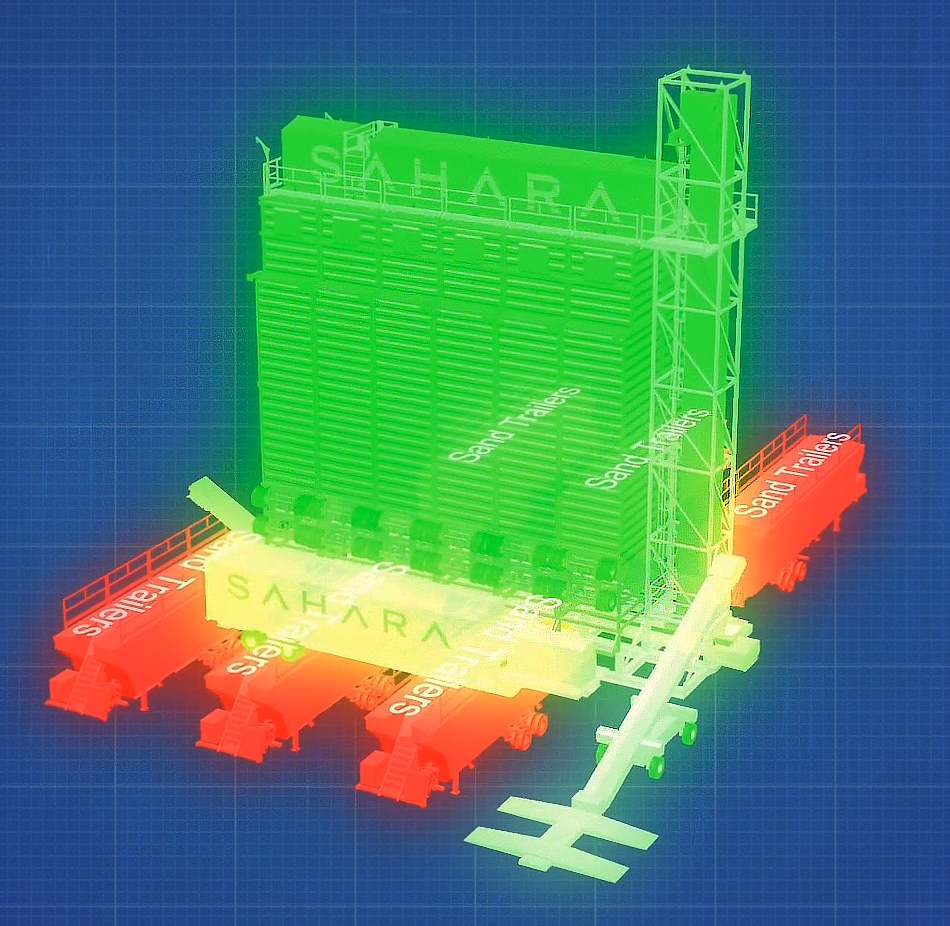

3D renderings have the potential to provide viewers with a unique experience. In this engineering animation, Trinity’s artists manipulated certain materials, in order to clarify information. For instance, they altered the color of certain items to make them stand out or draw attention to them. They also applied transparency to certain items so that viewers were able to observe the interior of the object and easily understand the process in a way that cannot be accomplished through live footage.

Several steps are demonstrated in this animation for the construction process of the Sahara Sand Source system. The entire animation is narrated illustrating each stage while the visuals follow along with the narration. First, rig matting is laid down on a flat and compacted surface. The next item, known as the skid is displayed being transported on the site by a semi-truck which is unfolded on top of the rig matting. As the animation transitions from step to step, the materials smoothly fade into place, omitting the unnecessary visuals. Next, the bucket elevator tower is stood up using a crane and picker. The twelve freestanding silos are then put in place along with the units distribution system. Finally, the system is brought online with a power unit, an electric generator, or a local power source. Once complete, the system can be loaded with proppant (a solid material, typically sand, treated sand, or man-made ceramic materials). Since Sahara’s silos are separate, it allows up to 12 different proppant types to be stored on site. When loading the sand, Sahara has a drive over system which allows trucks to unload up to five times faster than traditional methods. In the animation, the truck is displayed driving up to the unit, opening up the bottom hatch and going through the process.

The system lets the operator know the silos current capacity. During live operation, the pressure pumper instructs the Sahara field operator to start moving sand onto the transfer belt or directly into the blender. Since the transfer belt cannot be seen, Trinity artists apply transparency to all other items only displaying the sands path. A large volume of sand successfully flows through the unit and can be stopped at any moment.

3D animations have become an effective form of teaching detailed and complex systems like the Sahara Sand Source System. Trinity artists not only have the ability to create professional state of the art engineering animations but are able to communicate the information in the most beneficial way, as well as providing imagery that engages viewers throughout the video.

Industrial Sand in the U.S. Economy

According to the United States Geological Survey (the U.S.G.S.) Industrial sand and gravel, often termed ‘silica” and “silica sand” and “quartz sand” include high Si02 content sands and gravels. These sands are used in glassmaking, for foundry, abrasive and hydraulic fracturing applications, and many other uses. The U.S.G.S. further reports that silica resources for most markets are abundant. Leading producing states were Illinois, New Jersey, Michigan, Texas, and California. Sand and gravel mining has limited environmental impact except for temporarily disturbing the immediate environment while mining operations are active.

In 2017 the United States produced a total of 103,000 metric tons of industrial sand and gravel, up from 62,100 metric tons in 2013. According to Statistica.com most of the industrial sand production will be used for hydraulic fracturing and well-packing.

Useful Websites for the Sand Mining Industry

Petroleum Connection: http://www.petroleumconnection.com/digest

Fractracker Alliance: https://www.fractracker.org/2017/01/new-frac-sand-resources/

United States Geological Survey Minerals Information: https://minerals.usgs.gov/minerals/pubs/commodity/silica/